by Carl Shepherd

The history of buildings, the materials which are used in their construction, and the specific types of material and methods in which they are put together, are all part of what makes those structures fascinating.

Silver Creek Falls is home to approximately 177 roofed structures, the majority of which are either of log construction, or made from rough-sawn lumber - most of which was harvested from the trees located within the park and cut with an onsite sawmill.

The process of building construction and materials used frequently starts with a design characteristic or style. Silver Creek Falls buildings which are located within the historic districts have been constructed in the Rustic Adirondack architecture style. The National Park Service (NPS) employed this style in the 1930’s and 1940’s during the park building era across the nation. This style uses local native materials that blend within the landscape. An obvious advantage is relatively easy access to building materials that does not require long distance transportation. Whole, split, or peeled logs were used to provide the rugged look and native stone used to build stone porches and the massive fireplaces and chimneys.

Silver Creek Falls buildings vary from basic sleeper cabins at the Y Camp (Camp Silver Creek) which are primarily made from peeled logs and hand split shakes, to the more detailed South Falls Lodge involving larger logs, basalt stone, wooden doors and windows - all showing more skilled and detailed craftsmanship.

BUILDING WITH STICKS AND STONES

Preservation of historic buildings requires consideration of construction styles and techniques. A brief look of some of these techniques follows:

YMCA Staff Cabin

This is one of the more basic structures. These cabins were built using smaller logs, shakes, and rough-cut boards. The log members were not scribed to fit, but were simply laid one on top of another.

Interior view of ridge repair in staff cabin

Historic preservation seeks to retain as much of the original fabric of the building as possible. A lap joint technique is a simple joint used to repair log components in buildings and requires only the damaged wood to be replaced.

Close up view of repair on rafter tail

Almost invisible repair work indicates skilled craftsmanship

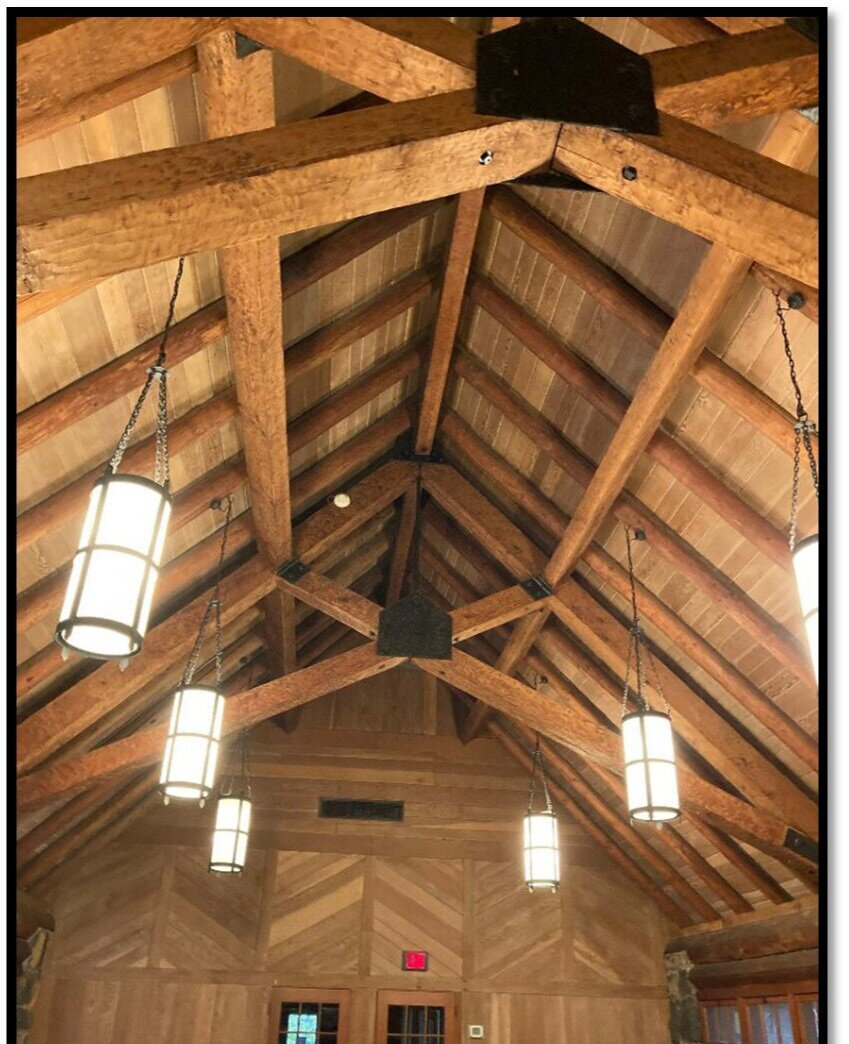

South Falls Lodge

South Falls Lodge construction, on the other hand, was much more detailed with a combination of whole peeled logs, sawn timber, and stonework. Large sawn timber purlins and cross beams support the peeled log rafters and sheathing boards. Exposed whole peeled log framework and detailed log work above the windows adds to the grand lodge design.

Using a scribe to transfer the profile of one log onto another

In contrast with the simply design of the cabins, logs in the Lodge were scribed to fit tightly. Scribing is a technique used to shape the log to the exact mould of the adjoining log.

Other construction material used was stone, specifically basalt. A thick bedrock of basalt covers a good portion of the Pacific Northwest from the Columbia River Basalt Flow episodes which occurred millions of years ago.

The use of basalt, even though located within the park, still requires huge amounts of energy to get it to the site and then shape it into a usable piece of material. Most of the work to shape the stone into building components was done by hand in the 1940’s when the South Falls Lodge was constructed.

Stones were split into basic sizes using drills, feathers, and wedges. Then further detailing was done with hand chisels and hammers. Needless to say this was very labor intensive.

Feathers (on the sides) of the wedge (center) are used to split large stone into workable pieces.

Drill marks from a star bit show where the original larger basalt stone was initially drilled and split.

BRINGING IT ALL TOGETHER

The use of these materials and tools requires skill and patience. Even more impressive is the practice of using log and stone together to create a structure that fits well together and is weather proof. This is where the scribe and getting two very different types of material to work together well becomes a learned skill. Note how the window trim was scribed to fit the profile of the basalt stone.

The final resting place! This is one of two grand fireplaces located within South Falls Lodge. Note the attention to detail in how closely the stones fit together. The final product of rustic construction style is a tribute to a group of guys trained to create a long-lasting example of craftsmanship.

Sources for further information:

https://www.nps.gov/parkhistory/online_books/mcclelland/mcclelland2d1.htm

https://www.fs.fed.us/t-d//pubs/pdfpubs/pdf15232802/1523-2802_Dovetails+Broadaxes_Sec508_08-09-17_WEB_150dpi.pdf